DETALLES

Plate Link Conveyor Belts

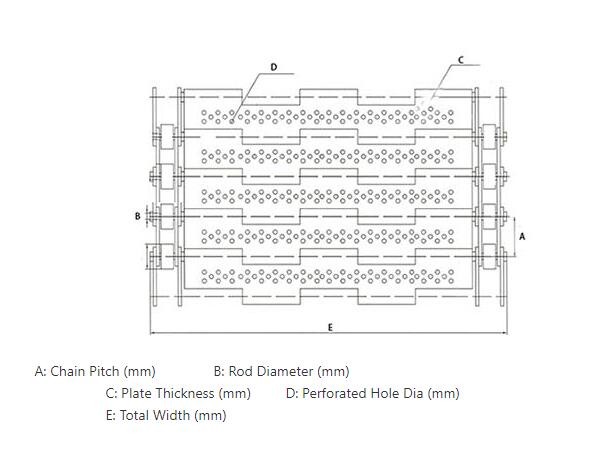

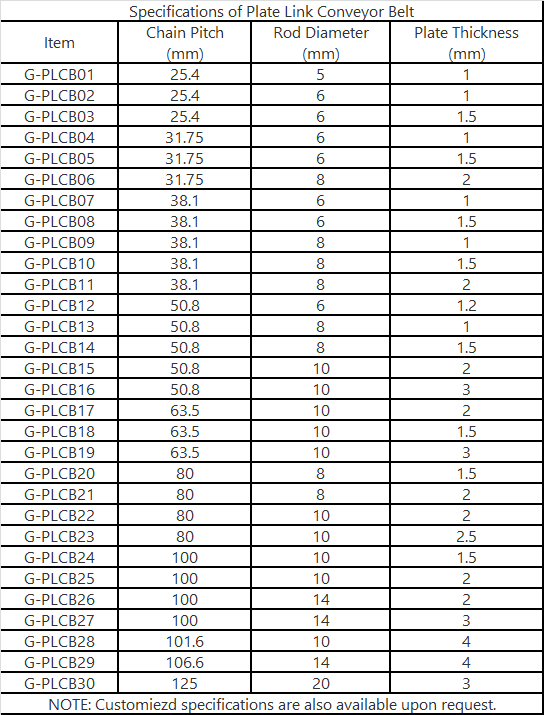

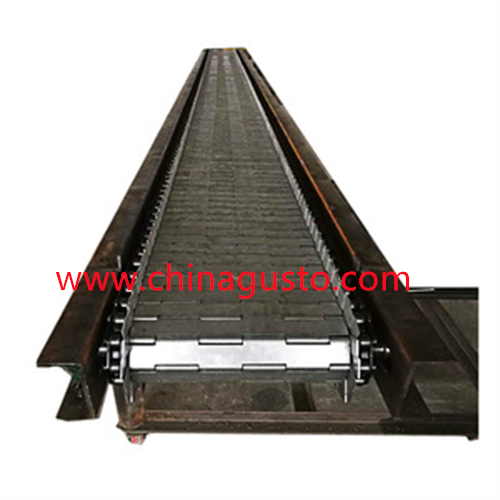

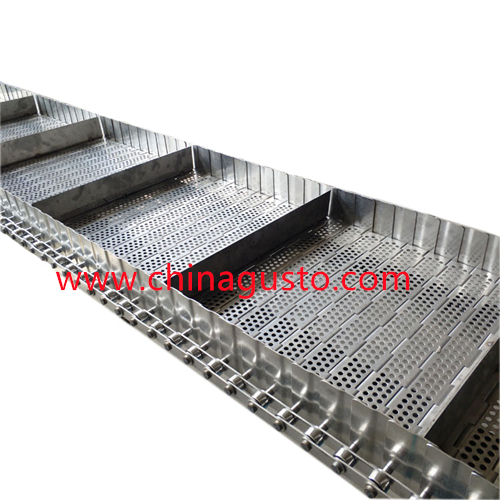

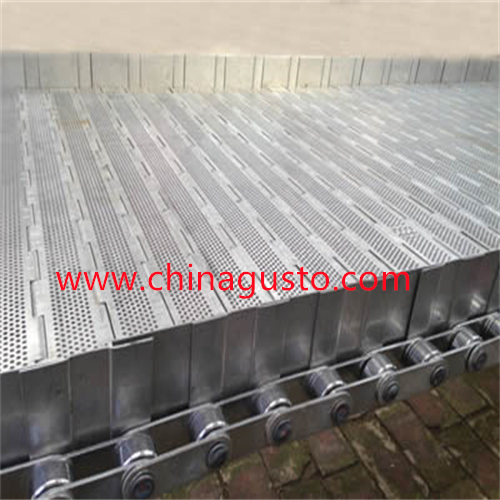

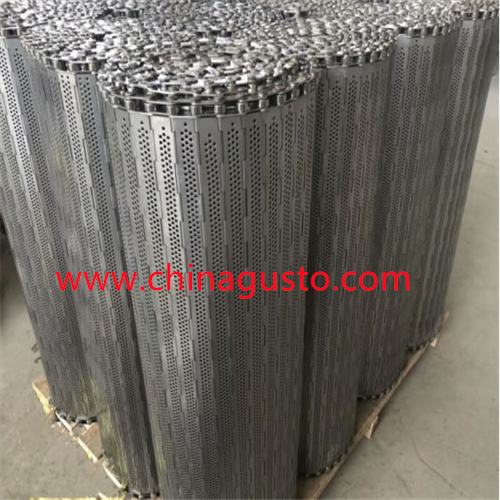

Plate link conveyor belt features an extremely robust design and high load capacity, making it the perfect choice for arduous engineering processes such as presswork, die-casting and forging. Its self-supporting structure makes it be used over large widths without any support, it could run smoothly in the conveying process, easy to install and replace, and long in service life.

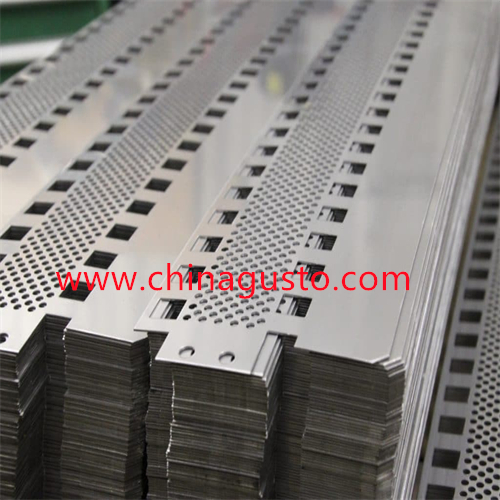

Plate conveyor belt consists of hinged slats with or without perforations. Perforated plate belt is ideal for drainage conveyor system. The size of perforation range from zero to very large, which could be customized.

Hinged plate belts have side plates and cross flights in various combinations of height and thickness to suit different customers' requirements. They can satisfy light to heavy load capacity. Chain edge plate belts are also available in side plates and cross flights.

Link plate conveyor belt are made by stainless steel T-304 or T-316. Both have superior corrosive resistance to suit most applications at elevated temperature.

Material available: carbon steel, SS 201, SS 304, SS 316.

Slat thickness: 0.8 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm.

Pitch: 19.05 mm, 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 76.2 mm.

Cross rod diameter: 5 mm, 6 mm, 8 mm, 10 mm, 12 mm.

Belt width: 200 mm – 4,000 mm.

Side plate thickness: 1.5, 2.0 or 3.0 mm.

Side plate height: 38.1, 50.8, 76.2, 101.6 or 152.4 mm.

Plate conveyor belt consists of hinged slats with or without perforations. Perforated plate belt is ideal for drainage conveyor system. The size of perforation range can be custom, its possibility to have of al kinds of perforations to fit the product production line.

Hinged plate belts have side plates and cross flights in various combinations of height and thickness to suit different customers' requirements. They can satisfy light to heavy load capacity. Chain edge plate belts are also available in side plates and cross flights. The chains at both ends can be fixed with cotter pins or washers, which are convenient to disassemble and maintain.

The link plate belts are tailor made and can be executed with pitches in almost any width and length and plate thickness .The link plate belt is positively driven by sprockets, and can be used at conveyor speeds of less than about 120 meters per minute.

Plate conveyor belt advantages

Temperature resistance, which can be used in production processes with temperatures of -30ºC to +600ºC infood and other industries.

Corrosion and rust resistance make it possible be used in the corrosive environments.

The baffles can be added onto the belt for convenient sorting and conveying.

The side guards can be added onto the belt to prevent products from spillage.

Chain link edge can ensure the smooth and high efficiency working.

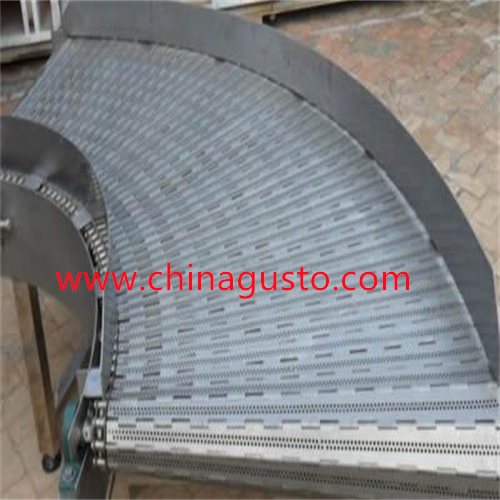

Curved perforated plate conveyor belt is available to suit more applications and equipment.

Suitable for arduous engineering processes such as press work, die-casting and forging.

Link plate belt needs minimal maintenance and will have a working life of many years.

Available belt type

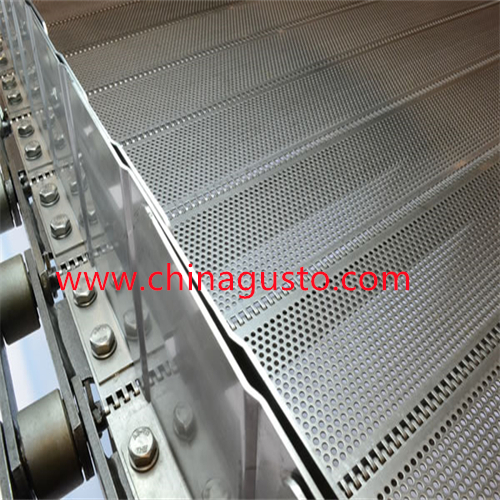

Plate conveyor belt consists of hinged slats with perforations

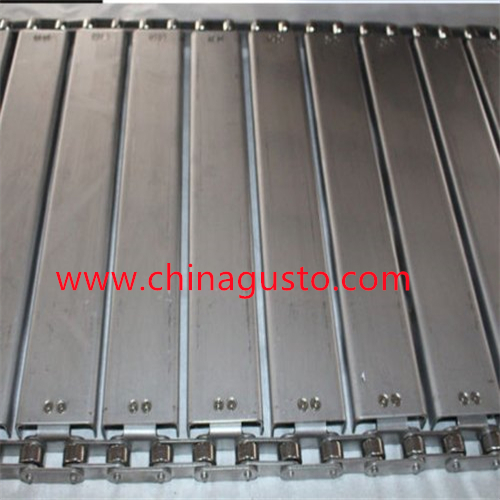

Plate conveyor belt consists of hinged slats without perforations

Plate conveyor belt with baffles can help to sort and convey products.

Available belt edge

Standard plate link conveyor belt

Plate link conveyor belt with side plate

Applications of plate link conveyor belt

Cooling systems

Washing systems

Waste treatment systems

Blanching systems

Sievingsystems

Drying systems

Sorting systems

Bread production systems

Product handling systems

Transport systems

Drainage systems

Sorting systems

Elevating systems

De-Elevating systems

Plate link conveyor belt features an extremely robust design and high load capacity, making it the perfect choice for arduous engineering processes such as presswork, die-casting and forging. Its self-supporting structure makes it be used over large widths without any support, it could run smoothly in the conveying process, easy to install and replace, and long in service life.

Plate conveyor belt consists of hinged slats with or without perforations. Perforated plate belt is ideal for drainage conveyor system. The size of perforation range from zero to very large, which could be customized.

Hinged plate belts have side plates and cross flights in various combinations of height and thickness to suit different customers' requirements. They can satisfy light to heavy load capacity. Chain edge plate belts are also available in side plates and cross flights.

Link plate conveyor belt are made by stainless steel T-304 or T-316. Both have superior corrosive resistance to suit most applications at elevated temperature.

Material available: carbon steel, SS 201, SS 304, SS 316.

Slat thickness: 0.8 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm.

Pitch: 19.05 mm, 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 76.2 mm.

Cross rod diameter: 5 mm, 6 mm, 8 mm, 10 mm, 12 mm.

Belt width: 200 mm – 4,000 mm.

Side plate thickness: 1.5, 2.0 or 3.0 mm.

Side plate height: 38.1, 50.8, 76.2, 101.6 or 152.4 mm.

Plate conveyor belt consists of hinged slats with or without perforations. Perforated plate belt is ideal for drainage conveyor system. The size of perforation range can be custom, its possibility to have of al kinds of perforations to fit the product production line.

Hinged plate belts have side plates and cross flights in various combinations of height and thickness to suit different customers' requirements. They can satisfy light to heavy load capacity. Chain edge plate belts are also available in side plates and cross flights. The chains at both ends can be fixed with cotter pins or washers, which are convenient to disassemble and maintain.

The link plate belts are tailor made and can be executed with pitches in almost any width and length and plate thickness .The link plate belt is positively driven by sprockets, and can be used at conveyor speeds of less than about 120 meters per minute.

Plate conveyor belt advantages

Temperature resistance, which can be used in production processes with temperatures of -30ºC to +600ºC infood and other industries.

Corrosion and rust resistance make it possible be used in the corrosive environments.

The baffles can be added onto the belt for convenient sorting and conveying.

The side guards can be added onto the belt to prevent products from spillage.

Chain link edge can ensure the smooth and high efficiency working.

Curved perforated plate conveyor belt is available to suit more applications and equipment.

Suitable for arduous engineering processes such as press work, die-casting and forging.

Link plate belt needs minimal maintenance and will have a working life of many years.

Available belt type

Plate conveyor belt consists of hinged slats with perforations

Plate conveyor belt consists of hinged slats without perforations

Plate conveyor belt with baffles can help to sort and convey products.

Available belt edge

Standard plate link conveyor belt

Plate link conveyor belt with side plate

Applications of plate link conveyor belt

Cooling systems

Washing systems

Waste treatment systems

Blanching systems

Sievingsystems

Drying systems

Sorting systems

Bread production systems

Product handling systems

Transport systems

Drainage systems

Sorting systems

Elevating systems

De-Elevating systems