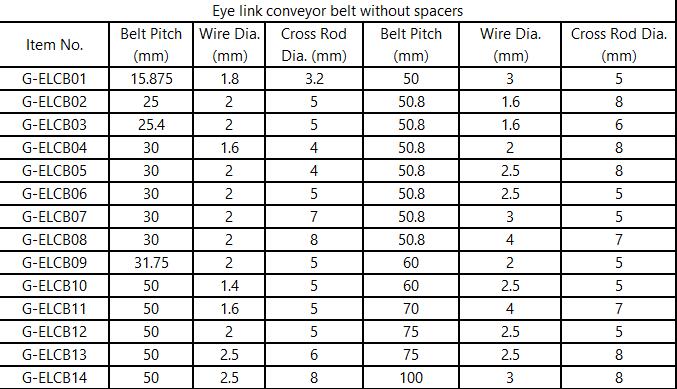

DETALLES

Eye Link Conveyor Belts

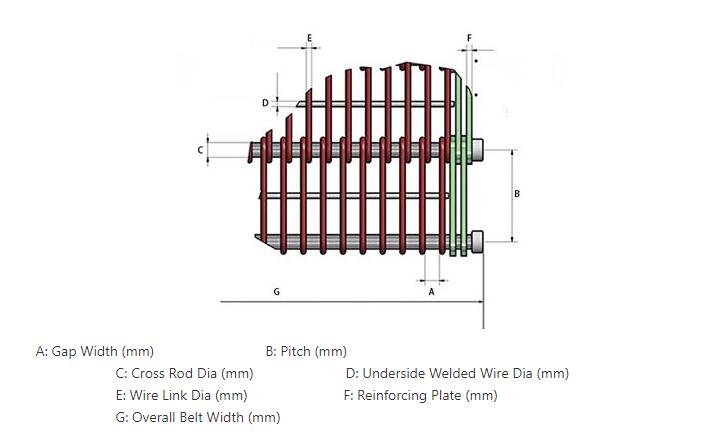

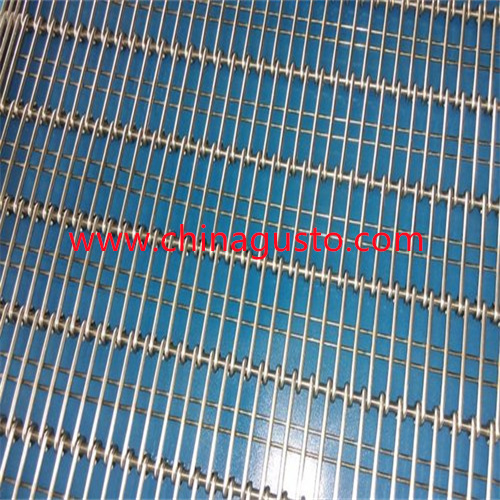

Eye Link Conveyor Belts, also named Wire Link Conveyor Belts, Eye-Flex Conveyor Belt, Wire Loop Belt. It consists of a series of eye links or eye link modules. Eyelink belting is the solution for heavy load conveying process. It combines strength, stable carrying surface, long lasting and limitless configurations, all of which make it an ideal conveyor belt in all conveying application in the food, chemical, pharmaceutical and packaging industries. Besides, side guard plates and cross flights are available on request. Side plates is designed to control the height of the product to be conveyed.

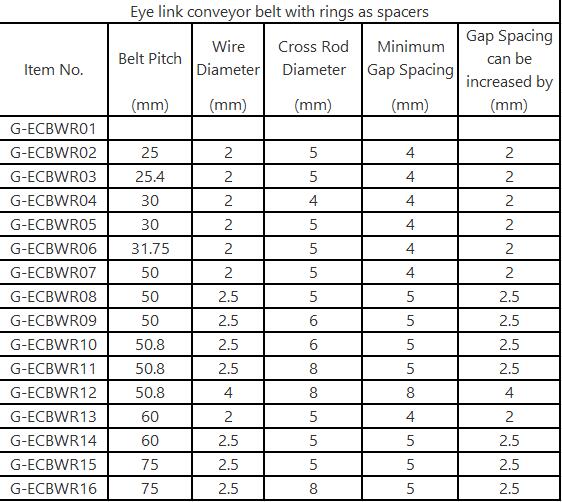

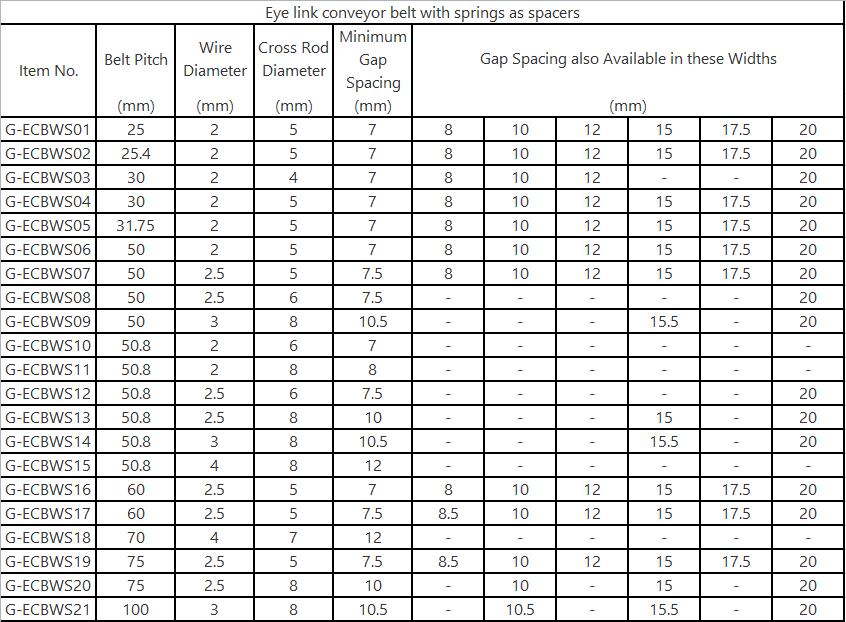

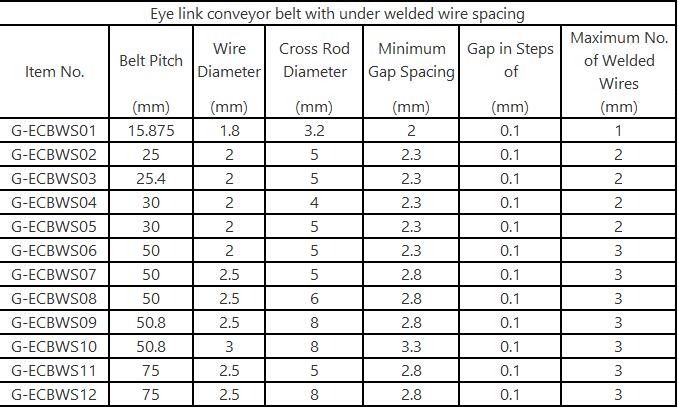

Eyelink modular belt has four constructions - full eyelink, eyelink with spring, eyelink with rings and eyelink with underwelded wire. Owing to the multiple constructions, eyelink belting can be manufactured into thousands styles to suit different applications. For example, if you need the conveyor belt which transfer very small products, full eyelink belts may be the first concern.

Specifications:

Material: SS 304, SS 316.

Chain pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

Rod diameter: 5 mm, 6 mm, 7 mm, 8 mm, 10 mm, 12 mm.

Wire diameter: 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

Spiral pitch: 2.4 mm to 100 mm.

Rod pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

Belt width: 200 mm to 6,000 mm.

Features & benefits:

Heavy-duty conveying requirements.

Flat carrying surface.

Multiple drive options.

Multiple spacers options.

Variable wire spacing.

Excellent air and fluid drainage.

Custom specification for special applications.

Numerous configuration options.

Cross flights and side guards provided.

Reduce downtime and maintenance.

Typical applications:

Baking.

Cooking.

Cooling.

Heating.

Drying.

Freezing.

Blanching.

Washing.

Frying

Sorting.

Grading.

Loading.

Elevating.

Belt Types

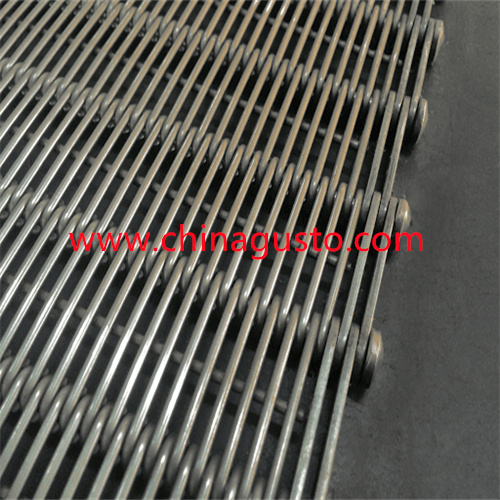

Eye Link Conveyor Belts has a standard construction based on a straight modular form. It is designed and built without spacers or perpendicularly welded under wires. This allows excellent flow-through in applications where no cross-support is required. Eye Link Conveyor Belts without spacers is also easily repaired with minimal cost.

Eye link conveyor belts — Available in six types that have their own specific advantages.

From eye link belts with pressed eye links to create the smallest opening possible to eyelink belts with springs to guarantee good shock resistance and resistance to lateral forces — Eye link Conveyor Belt has many types of eyelink belts that each have their own specific advantages.

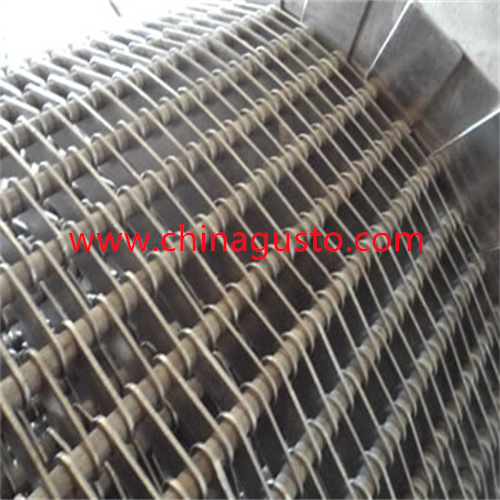

Full Eye link belt

On a full eye link belt the eyelinks lie against each other, and the opening is equal to the wire diameter. It is designed and built without spacers or perpendicularly welded under wires. This allows excellent flow-through in applications where no cross-support is required. The belt is often used in food processing for its flat conveying surface, open mesh configuration, and ease of cleaning. This type eye Link Conveyor Belt without spacers is also easily repaired with minimal cost.

Pressed Eye link belt

Some applications require the smallest opening possible. By flattening the eyes of the eye links the opening between the links becomes smaller. This type is very appropriate for small and fine-structured products.

Welded Eye link belt

The eye links are welded on to an location wire, so that a module is created. Very narrow and very wide openings can be created, depending on the processing of the products concerned.The underwelded wire eliminates the potential bacteria traps under the spacers, springs, rings, and sleeves. This configuration makes cleaning and sanitation easy and more efficient.

Pressed and Weled Eye link belt

Some applications require a stable belt in combination with a small opening/drain. The accuracy of our welding process allows us to produce modules with very small intervals between the eye links. The modular structure makes the assembly of very broad belts possible.

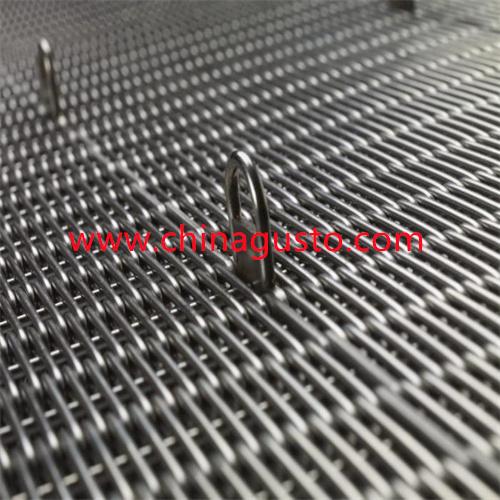

Eye link belt with spring

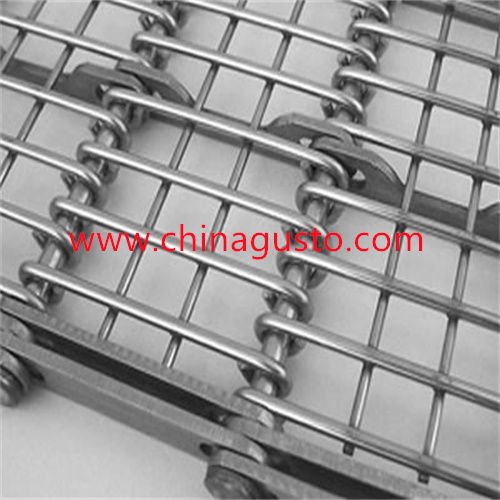

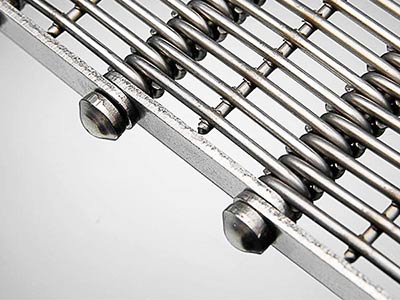

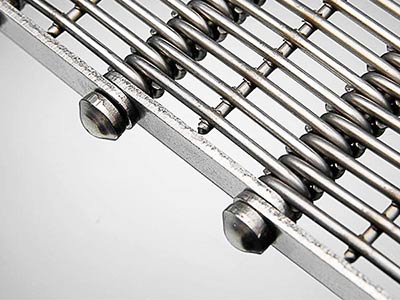

Springs help create a more dimensionally stable belt in heating or freezing applications. These belts are more dimensionally stable because the wires are able to move on the cross rod. Springs also expose a large proportion of the connecting rod for improved cleaning and sanitizing. The placement of springs between the eye links ensures that they are positioned at regular intervals. The result is a relatively light belt with specific qualities, such as a good shock resistance and resistance to lateral forces.

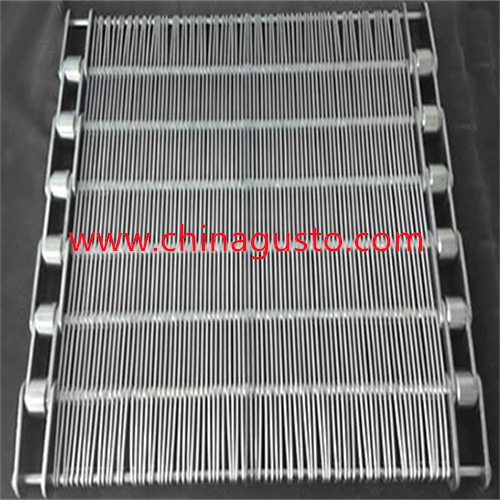

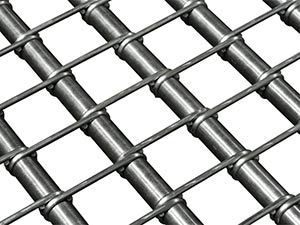

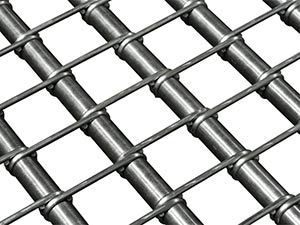

Eye link blet with bushings or washers

This versatile variation of eye link belt uses bushings or washers between the wires to increase the belt gap. By increasing the belt gap, more air will circulate around the bottom of the product. Increasing the product exposure to this additional air flow improves the efficiency of your process. When bushings or washers are added the belts become heavier and more rigid.

Available edges:

Eye link belt with Welded Edge

At both sides the belt is fitted with plate links, and the far ends of the cross rods are fitted with washers and subsequently welded. This results in a thorough finishing of the belt in combination with the desired bearing surface.

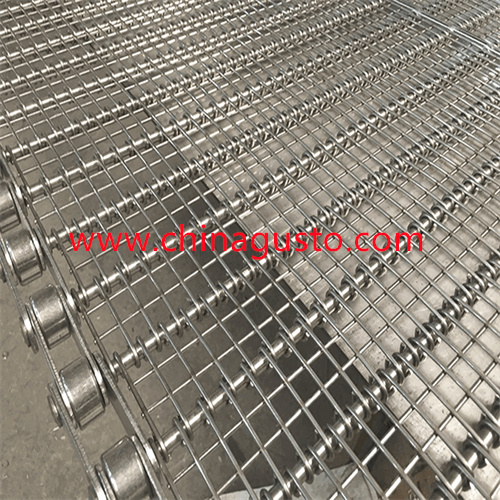

Eye link belt with reinforcing plate

Reinforcing plates are the typical edge style. These are solid metal plates added before the connecting rod is welded. The belt edges are generally formed by two ore more rows of plate links. The wire links and plate links are assembled on the cross rod which is fitted on both sides with a welded ring or a butted head. Additional reinforcing plates can be added at the edge of the belt, or at specified increments across the belt width to further enhance the strength of this belt.

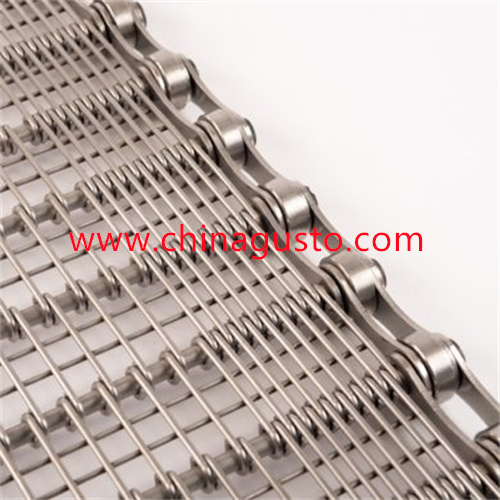

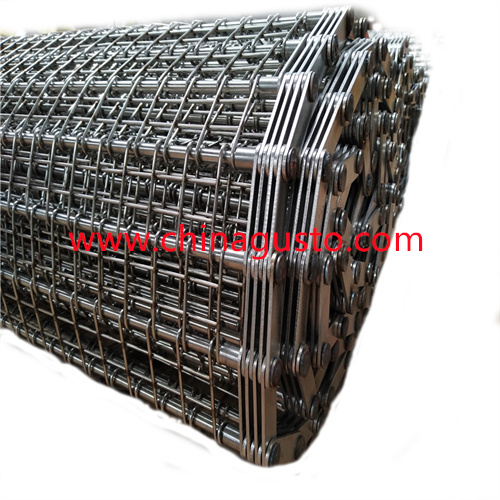

Eye link belt with chain edge

The belt edges are formed by a hollow pin chain. The links and chains are assembled on the cross rod which is fitted on both sides with a welded ring. The chain is mostly kept in place by welding a ring to the outside as well as to the inside of the chain. If the ends of the cross rods are narrowed, the inside of the chain is secured by this narrowing and the inner ring is cancelled. Chain edges on Eye link belts as an alternative method for driving the belt for enhanced tracking and reliability.

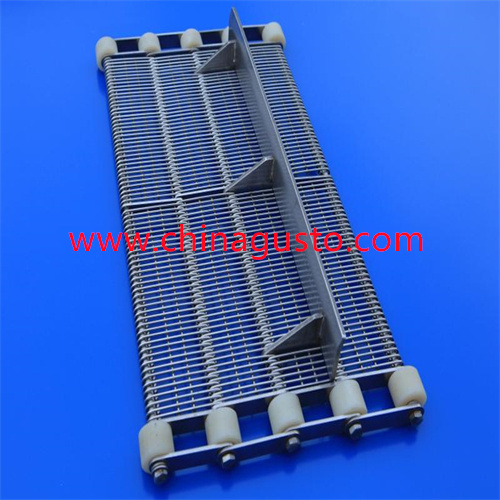

Eye link belt with side guard

Eye Link belts can be equipped with side guards to prevent product from falling off the side of the belt. Height and shape of the side guards can be customized for your product or application. These side guards can also be inserted at various points across the belt width providing a positive separation between rows of product.

Eyelink conveyor belts combine a flat, stable surface with the dimensional stability and robustness of metal and are well suited to convey heavy loads and unstable or fragile products that require good support from the conveyor belt.

Eye Link Conveyor Belts, also named Wire Link Conveyor Belts, Eye-Flex Conveyor Belt, Wire Loop Belt. It consists of a series of eye links or eye link modules. Eyelink belting is the solution for heavy load conveying process. It combines strength, stable carrying surface, long lasting and limitless configurations, all of which make it an ideal conveyor belt in all conveying application in the food, chemical, pharmaceutical and packaging industries. Besides, side guard plates and cross flights are available on request. Side plates is designed to control the height of the product to be conveyed.

Eyelink modular belt has four constructions - full eyelink, eyelink with spring, eyelink with rings and eyelink with underwelded wire. Owing to the multiple constructions, eyelink belting can be manufactured into thousands styles to suit different applications. For example, if you need the conveyor belt which transfer very small products, full eyelink belts may be the first concern.

Specifications:

Material: SS 304, SS 316.

Chain pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

Rod diameter: 5 mm, 6 mm, 7 mm, 8 mm, 10 mm, 12 mm.

Wire diameter: 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

Spiral pitch: 2.4 mm to 100 mm.

Rod pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

Belt width: 200 mm to 6,000 mm.

Features & benefits:

Heavy-duty conveying requirements.

Flat carrying surface.

Multiple drive options.

Multiple spacers options.

Variable wire spacing.

Excellent air and fluid drainage.

Custom specification for special applications.

Numerous configuration options.

Cross flights and side guards provided.

Reduce downtime and maintenance.

Typical applications:

Baking.

Cooking.

Cooling.

Heating.

Drying.

Freezing.

Blanching.

Washing.

Frying

Sorting.

Grading.

Loading.

Elevating.

Belt Types

Eye Link Conveyor Belts has a standard construction based on a straight modular form. It is designed and built without spacers or perpendicularly welded under wires. This allows excellent flow-through in applications where no cross-support is required. Eye Link Conveyor Belts without spacers is also easily repaired with minimal cost.

Eye link conveyor belts — Available in six types that have their own specific advantages.

From eye link belts with pressed eye links to create the smallest opening possible to eyelink belts with springs to guarantee good shock resistance and resistance to lateral forces — Eye link Conveyor Belt has many types of eyelink belts that each have their own specific advantages.

Full Eye link belt

On a full eye link belt the eyelinks lie against each other, and the opening is equal to the wire diameter. It is designed and built without spacers or perpendicularly welded under wires. This allows excellent flow-through in applications where no cross-support is required. The belt is often used in food processing for its flat conveying surface, open mesh configuration, and ease of cleaning. This type eye Link Conveyor Belt without spacers is also easily repaired with minimal cost.

Pressed Eye link belt

Some applications require the smallest opening possible. By flattening the eyes of the eye links the opening between the links becomes smaller. This type is very appropriate for small and fine-structured products.

Welded Eye link belt

The eye links are welded on to an location wire, so that a module is created. Very narrow and very wide openings can be created, depending on the processing of the products concerned.The underwelded wire eliminates the potential bacteria traps under the spacers, springs, rings, and sleeves. This configuration makes cleaning and sanitation easy and more efficient.

Pressed and Weled Eye link belt

Some applications require a stable belt in combination with a small opening/drain. The accuracy of our welding process allows us to produce modules with very small intervals between the eye links. The modular structure makes the assembly of very broad belts possible.

Eye link belt with spring

Springs help create a more dimensionally stable belt in heating or freezing applications. These belts are more dimensionally stable because the wires are able to move on the cross rod. Springs also expose a large proportion of the connecting rod for improved cleaning and sanitizing. The placement of springs between the eye links ensures that they are positioned at regular intervals. The result is a relatively light belt with specific qualities, such as a good shock resistance and resistance to lateral forces.

Eye link blet with bushings or washers

This versatile variation of eye link belt uses bushings or washers between the wires to increase the belt gap. By increasing the belt gap, more air will circulate around the bottom of the product. Increasing the product exposure to this additional air flow improves the efficiency of your process. When bushings or washers are added the belts become heavier and more rigid.

Available edges:

Eye link belt with Welded Edge

At both sides the belt is fitted with plate links, and the far ends of the cross rods are fitted with washers and subsequently welded. This results in a thorough finishing of the belt in combination with the desired bearing surface.

Eye link belt with reinforcing plate

Reinforcing plates are the typical edge style. These are solid metal plates added before the connecting rod is welded. The belt edges are generally formed by two ore more rows of plate links. The wire links and plate links are assembled on the cross rod which is fitted on both sides with a welded ring or a butted head. Additional reinforcing plates can be added at the edge of the belt, or at specified increments across the belt width to further enhance the strength of this belt.

Eye link belt with chain edge

The belt edges are formed by a hollow pin chain. The links and chains are assembled on the cross rod which is fitted on both sides with a welded ring. The chain is mostly kept in place by welding a ring to the outside as well as to the inside of the chain. If the ends of the cross rods are narrowed, the inside of the chain is secured by this narrowing and the inner ring is cancelled. Chain edges on Eye link belts as an alternative method for driving the belt for enhanced tracking and reliability.

Eye link belt with side guard

Eye Link belts can be equipped with side guards to prevent product from falling off the side of the belt. Height and shape of the side guards can be customized for your product or application. These side guards can also be inserted at various points across the belt width providing a positive separation between rows of product.

Eyelink conveyor belts combine a flat, stable surface with the dimensional stability and robustness of metal and are well suited to convey heavy loads and unstable or fragile products that require good support from the conveyor belt.