DETALLES

Chain Link Conveyor Belts

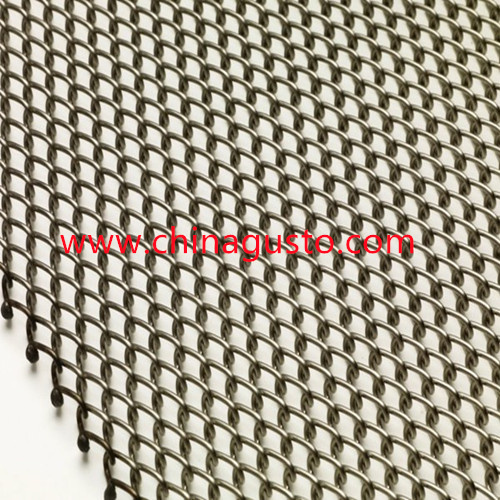

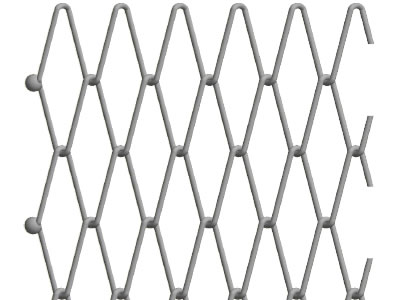

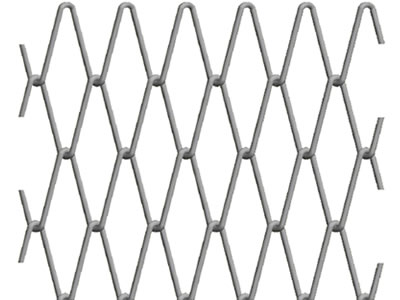

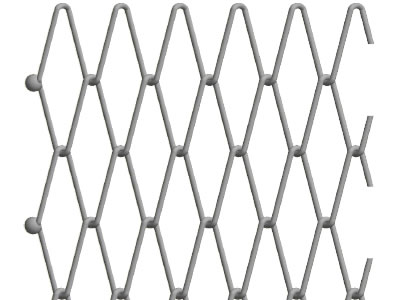

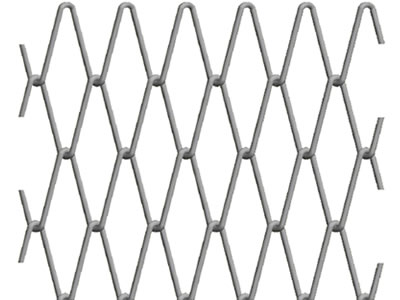

Chain Link Conveyor Belt, also called stainless steel wire mesh belt or conventional mesh belt. Chain Link belt features a simplistic design, where successive spiral coils are interwoven to create an open mesh. Chain Link can be supplied with welded edges, knuckled edge and chain edge. With considering the belt design both simple and functional, we offer our clients with an economic and lightweight solution for low load conveying applications, mainly for light duty use in drying and cooling applications.

The light belts of the wire mesh belt consist of belt segments linked with splicing rods. The individual elements consist of alternating right and left-hand round wire spirals in a flat oval or round form. The edges of the wire mesh belt are available in a welded or bent design.

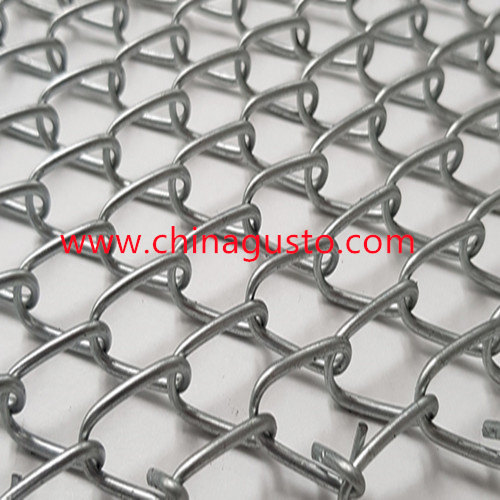

Different from balanced weave belt consisting of alternating left-hand and right-hand spiral coils chain link conveyor belting is constructed by unidirectional coils. For a friction driven belt, the belt features alternating sections of left-hand then right-hand. To counteract the tracking issues caused by the unidirectional coil pattern, cross rods are inserted across the belts - one is right-hand woven and the other is right-hand woven.

Chain link conveyor belting consists of interwoven successive spiral wire, which looks like chain link fencing. This universal conveyor belt is the simplest wire belt but functional and economical in conveying light-duty applications. Owing to its large open area, chain link belt makes itself an ideal choice for drying, cooling and heating where energy efficiency is the most important.

Features of chain link conveyor belt

Simple structure. It is made of several spiral coils. Suitable for light-duty use in drying and cooling applications

Economical. Economic and lightweight solution for low load conveying applications. The simple structure make it economical than other types of conveyor belt.

Functional. The stainless steel chain link conveyor belt is suitable for lifting, conveying lightweight products.

Different edge. We can supply welded or knuckled edge for your choice.

Baffles are available. Side and center baffles can be added to the conveyor belt. Baffles can prevent the products from falling down to the ground. It is also useful for sorting and conveying.

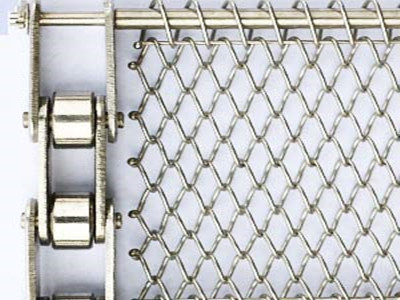

Chain link drive. The chain link drive pattern can ensure the smooth and high efficient working.

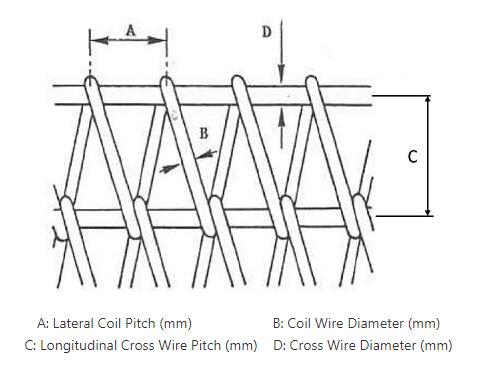

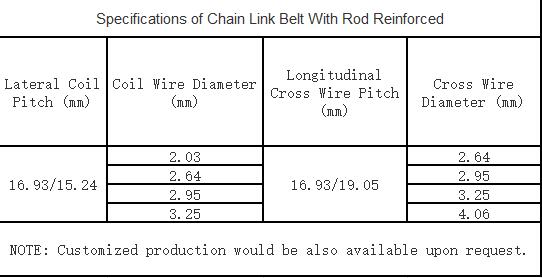

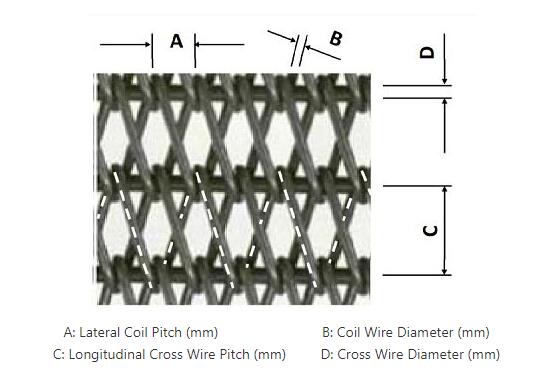

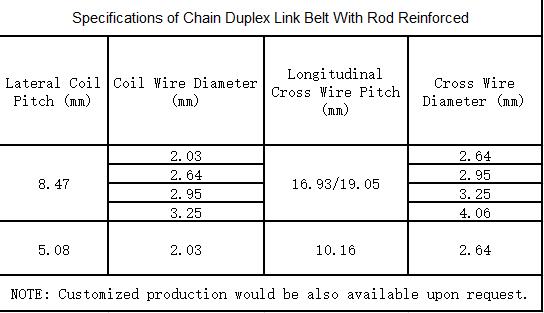

Specifications:

Standard chain link belt can be supplied with welded or knuckled edge finish.

Welded edge - Spiral coil wires are looped and welded together. It is the most economical edge finish. This kind of finish allows for relatively smooth finish.

Knuckled edge - Each coil wire is bent back into a 'U' shape and then interlock with the nearest coil. This knuckled edge allows for great flexibility and reduces stress building up at these connecting positions.

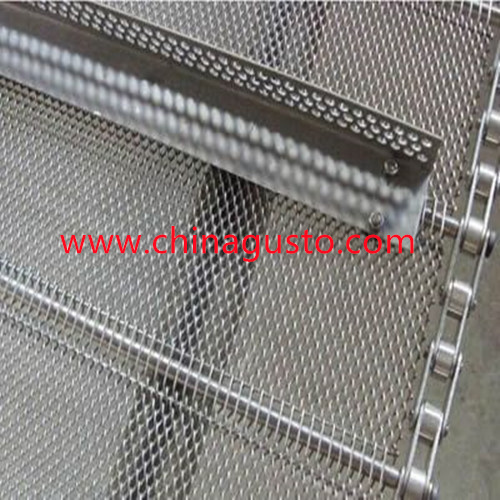

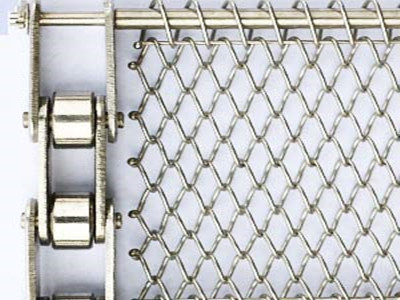

Chain edge - Along with the mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then through chains at the edges of the mesh

Chain Link Conveyor Belt, also called stainless steel wire mesh belt or conventional mesh belt. Chain Link belt features a simplistic design, where successive spiral coils are interwoven to create an open mesh. Chain Link can be supplied with welded edges, knuckled edge and chain edge. With considering the belt design both simple and functional, we offer our clients with an economic and lightweight solution for low load conveying applications, mainly for light duty use in drying and cooling applications.

The light belts of the wire mesh belt consist of belt segments linked with splicing rods. The individual elements consist of alternating right and left-hand round wire spirals in a flat oval or round form. The edges of the wire mesh belt are available in a welded or bent design.

Different from balanced weave belt consisting of alternating left-hand and right-hand spiral coils chain link conveyor belting is constructed by unidirectional coils. For a friction driven belt, the belt features alternating sections of left-hand then right-hand. To counteract the tracking issues caused by the unidirectional coil pattern, cross rods are inserted across the belts - one is right-hand woven and the other is right-hand woven.

Chain link conveyor belting consists of interwoven successive spiral wire, which looks like chain link fencing. This universal conveyor belt is the simplest wire belt but functional and economical in conveying light-duty applications. Owing to its large open area, chain link belt makes itself an ideal choice for drying, cooling and heating where energy efficiency is the most important.

Features of chain link conveyor belt

Simple structure. It is made of several spiral coils. Suitable for light-duty use in drying and cooling applications

Economical. Economic and lightweight solution for low load conveying applications. The simple structure make it economical than other types of conveyor belt.

Functional. The stainless steel chain link conveyor belt is suitable for lifting, conveying lightweight products.

Different edge. We can supply welded or knuckled edge for your choice.

Baffles are available. Side and center baffles can be added to the conveyor belt. Baffles can prevent the products from falling down to the ground. It is also useful for sorting and conveying.

Chain link drive. The chain link drive pattern can ensure the smooth and high efficient working.

Specifications:

- Material: carbon steel, SS 201, SS 304, SS 316.

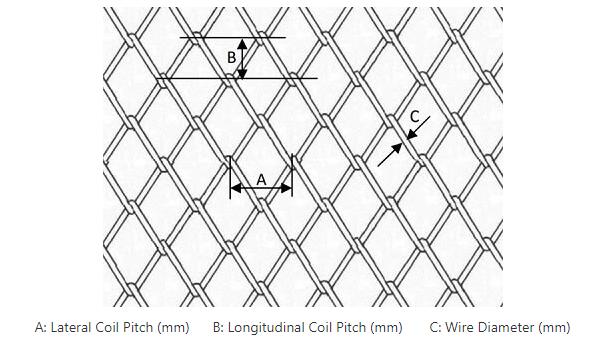

- Wire diameter: 1.2 mm, 1.4 mm, 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

- Spiral pitch: 6 mm to 40 mm.

- Rod pitch: 5 mm to 30 mm.

- Belt width: 200 mm to 5,000 mm.

- The most economical belt for low load conveying applications.

- Large open area ideal for drying and cooling.

- Supplied with welded or knuckled edge finishes.

- Friction-driven belt.

- Stainless steel T-304 available.

- Welded or knuckled edge finish.

- Cooling.

- Drying.

- Lift guards.

- Heating.

- Transport light-duty products.

- Industrial curtains.

Standard chain link belt can be supplied with welded or knuckled edge finish.

Welded edge - Spiral coil wires are looped and welded together. It is the most economical edge finish. This kind of finish allows for relatively smooth finish.

Knuckled edge - Each coil wire is bent back into a 'U' shape and then interlock with the nearest coil. This knuckled edge allows for great flexibility and reduces stress building up at these connecting positions.

Chain edge - Along with the mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then through chains at the edges of the mesh