DETALLES

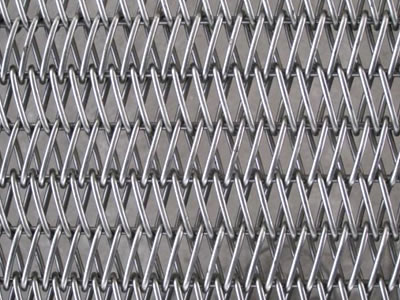

Balanced Spiral Woven Metal Conveyor Belts for Industrial Product Processing, Transfer and Packaging Belts

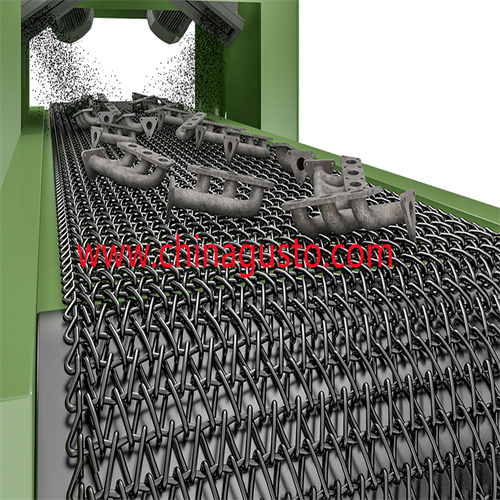

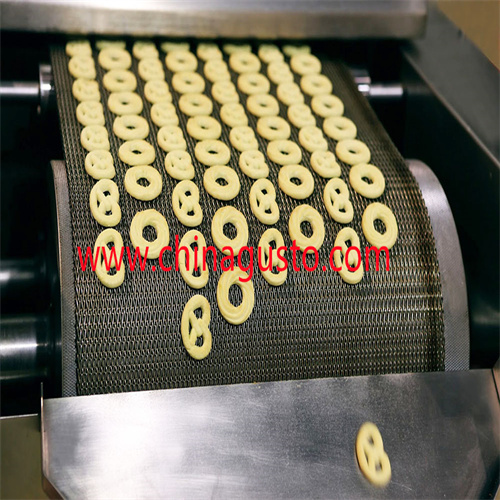

Due to its characteristics of true travel, good flexibility, excellent strength-to-weight ratio, flat surface and minimal maintenance. Balanced Spiral belt has been an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications.

There are three types of driving methods - positive drive, friction drive and chain drive. Each has its own character. Please tell us before ordering.

Product description:

Features & benefits:

Cooking

Heating

Cooling

Coating

Drainage

Baking

Industrial Curtains

Annealing

Curing

Shrink-Wrapping

Lifting Slings

Elevating

Cladding

Mesh available:

Edge finish available:

Due to its characteristics of true travel, good flexibility, excellent strength-to-weight ratio, flat surface and minimal maintenance. Balanced Spiral belt has been an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications.

There are three types of driving methods - positive drive, friction drive and chain drive. Each has its own character. Please tell us before ordering.

Product description:

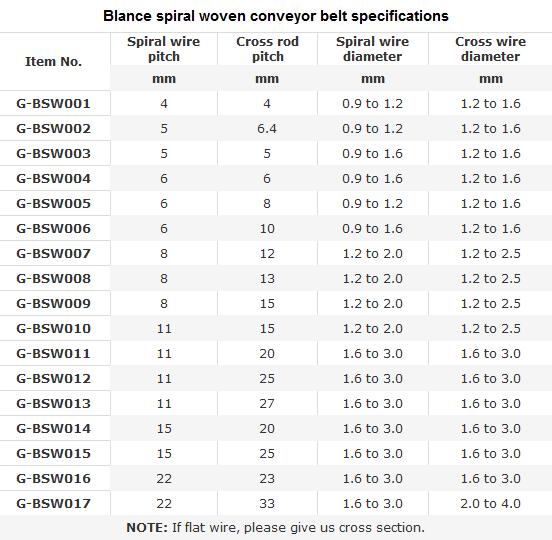

- Item: Balanced Spiral Woven Metal Conveyor Belts

- Wire diameter: 1.2 mm, 1.4 mm, 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

- Cross wire diameter: 1.2 mm – 4.0 mm.

- Flat wire size: 1.0 mm × 0.7 mm to 6.0 mm × 3.0 mm.

- Spiral wire pitch: 2.8 mm to 40 mm.

- Cross rod pitch: 5 mm to 50.8 mm.

- Belt width: 200 mm to 5,000 mm.

- Max. Working temperature: depending on the material 550°C~1200°C

- Material available: carbon steel, SS 201, SS 304, SS 316, SS 314.

Features & benefits:

- Alternating left and right hand spiral coils.

- Excellent tracking properties.

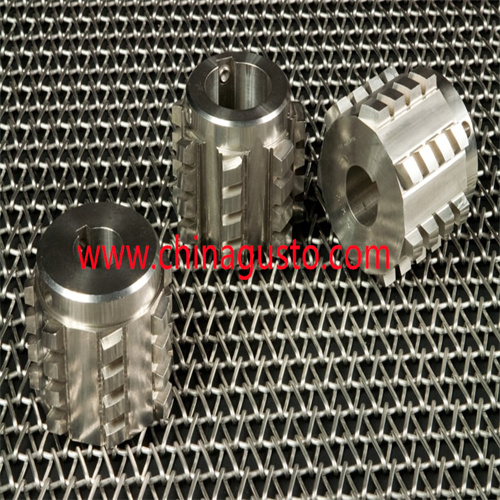

- Friction-drive, positive drive and chain edge drive.

- Chain edge for heavy load applications.

- Straight-running operation.

- Excellent strength-to-weight ratio.

- Wide variety of mesh specifications for individual application.

- Maximum flexibility.

- Cross-flights and side plates available.

Cooking

Heating

Cooling

Coating

Drainage

Baking

Industrial Curtains

Annealing

Curing

Shrink-Wrapping

Lifting Slings

Elevating

Cladding

Mesh available:

-

-

Standard balanced weave belt

This wire belt consists of single alternating left and right-hand spiral coils connecting by a crimped cross wire. -

-

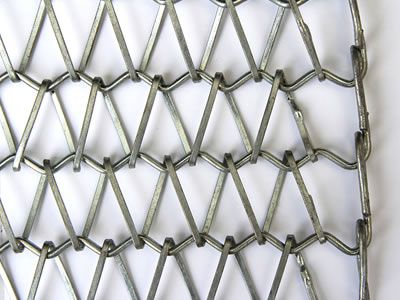

Double balanced weave belt

It uses alternating double left-hand and right-hand spiral coils connected by a crimped cross rod. This kind mesh belt allows for carrying heavy-load small products at elevated temperature. -

-

Flat wire balanced weave belt

Flat coil wire is frequently used for more stable carrying surface. Flat wire interconnects by straight or crimped cross rods. -

-

Double wire balanced weave belt

Double coil wires interconnecting by crimped cross rods are available on request. It is designed for carrying heavier products.

Edge finish available:

- Welded edge - This is the most popular and economical edge finish. Both spiral coils and crimp cross wire are welded together without cut wire ends.

-

- Hook edge - This is less popular than the welded edge finish. It is an option in applications where welding facilities are not workable. This kind of edge finish is also smooth and flexible. Generally speaking, it is available for conveyor mesh with a relatively large cross wire pitch.

-

- Laddered edge - It is less common than the welded edge. It is also an option for the applications where welded edge finish is not possible. It is the better choice for high temperature applications. Similar to hook edge, it is also available for mesh with large cross wire pitch.

-

- Chain edge - The three edge finishes above can be driven by side chains using cross rods.